Coil Weld Angle Bracket™

Coil Weld Angle Bracket™

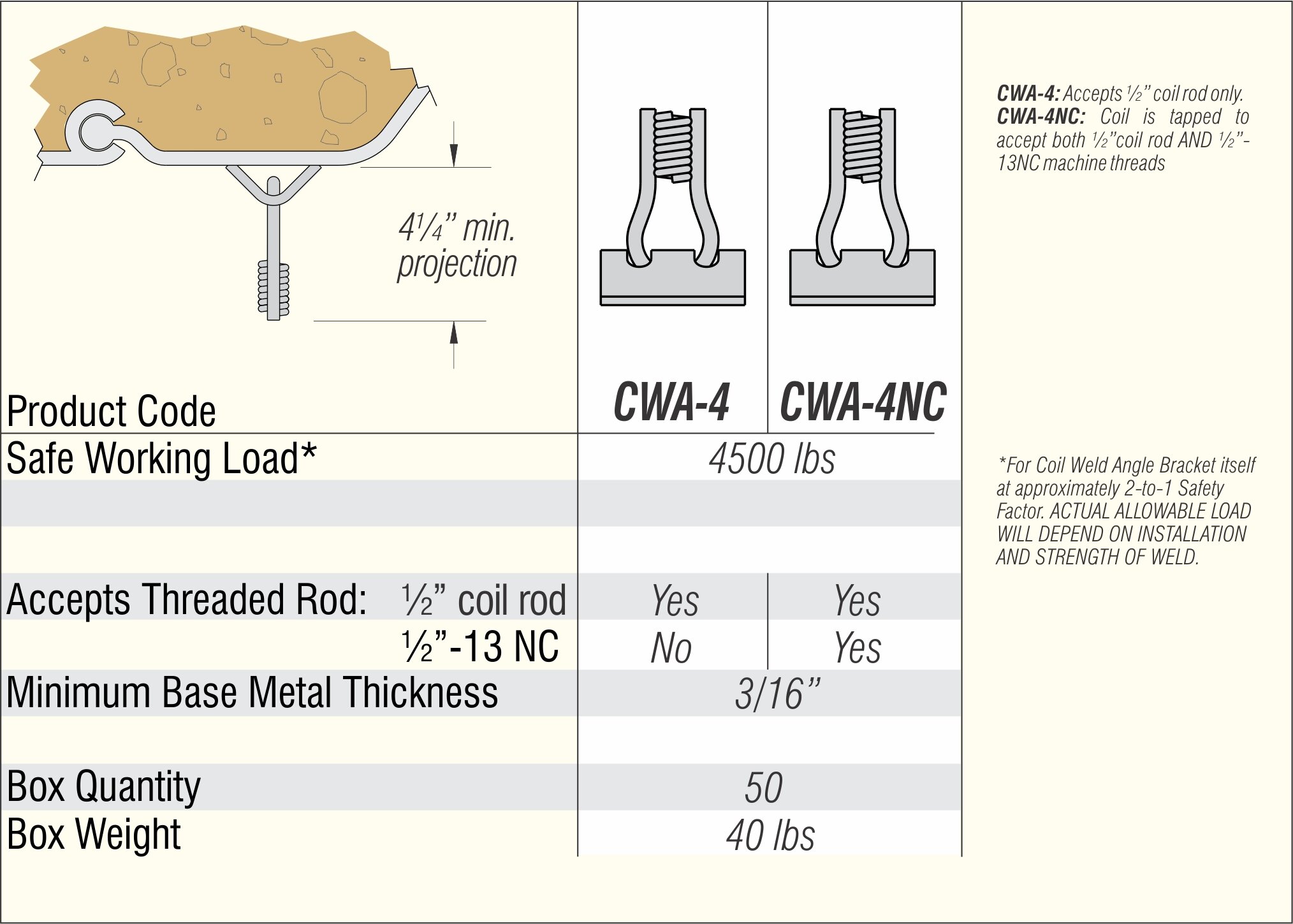

Steel Dog® Coil Weld Angle Brackets™ are a low-cost way to tie formwork to steel structures where manual (stick, MIG) welding is to be used (for stud welding, try the Steel Dog® Coil-Stud™). Typical application: one-sided forming against soldier piles or sheet piling.

Available in various sizes for:

1/2” coil rod

3/4” coil rod

15mm (5/8”) euro rod

20mm euro rod

FEATURES:

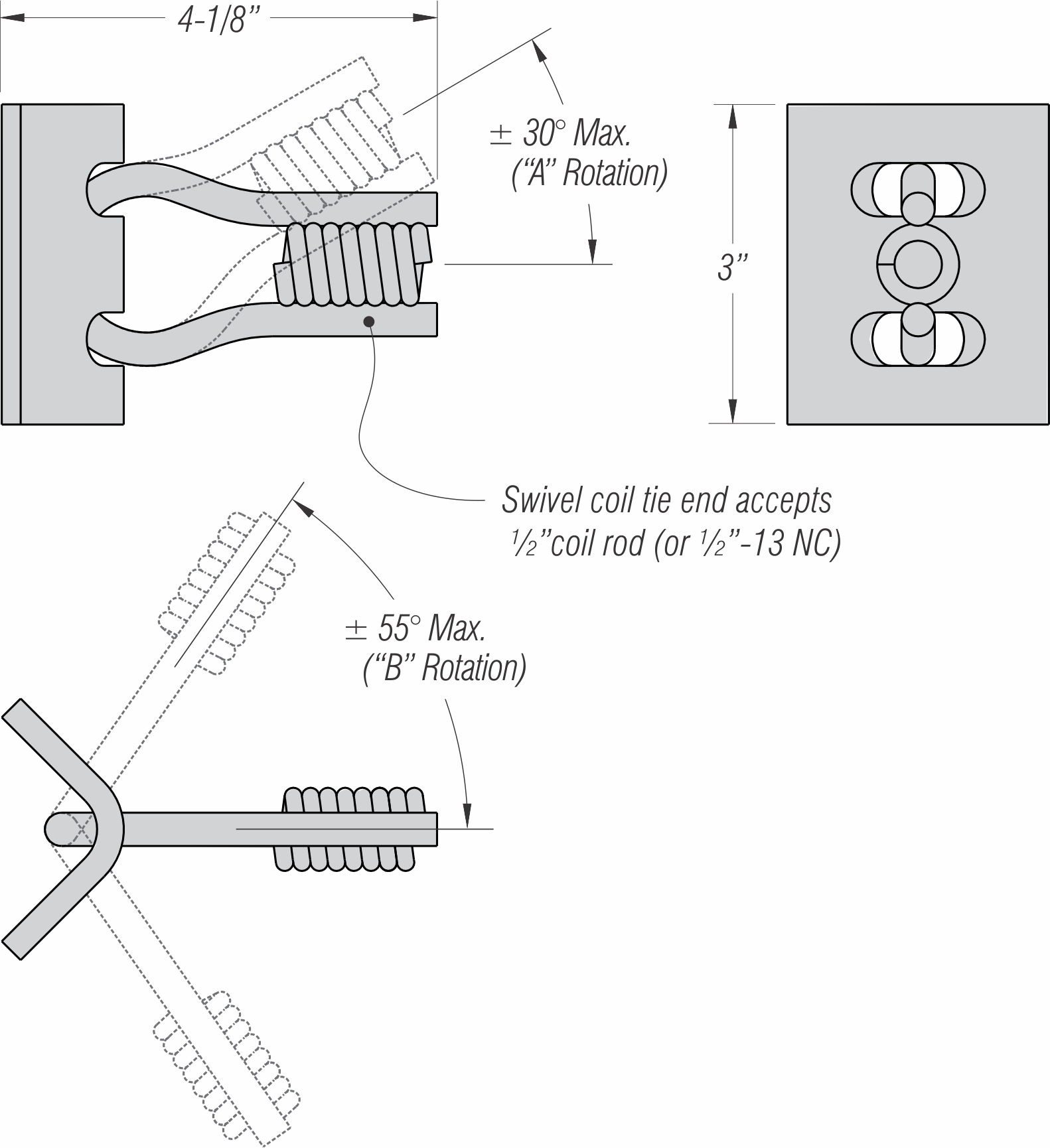

Swivel loop coil tie end to accommodate misalignment between bracket placement and formwork tie location.

Accepts standard ½”coil rod or ½”-13 NC rod (SCS-4NC)

Eliminates expensive external bracing or welding.

MATERIAL:

Bracket: HSLA Grade 50 steel. Swivel loop wire is AISI C1035.

FINISH:

None

MAXIMUM SAFE WORKING LOAD:

4500 Lbs. (2-to-1 safety factor) when welded as directed below. When properly welded, this load may be applied to the coil loop at any permissible orientation (±30° in “A” rotation, and ±55° in “B” rotation, or any combination of the two).

INSTALLATION:

Coil Weld Angle Brackets should be welded by a certified welder using industry standard AWS practices.

The use of low hydrogen welding wire or rod is recommended.

Bracket should be welded with a continuous fillet where both 3” wide legs contact base metal. Fillets should extend around the ends of each leg.