Snap-Coil™ Tie

Snap-Coil™ Tie

The Steel Dog Snap-Coil™ Tie is a multipurpose Transition Tie for “job-built” plywood concrete forms. With a button head snap tie electronically welded to a ½”coil tie end, the Snap-Coil™ Tie gives the user the versatility using of threaded coil rod for one-sided forming, long ties, and other purposes, while still using familiar, low-labor-cost means of attachment to formwork (slotted wedges, Jahn brackets).

FEATURES:

Threads onto standard ½”coil rod

Snaps off like normal button-head snap-tie

Low cost solution for one-sided forming and adjustable-length ties

Welded to rigorous standards using computer-controlled equipment: each SC is as strong as a standard button-head snap-tie

MATERIAL:

Snap tie end and wire struts: AISI C1038 carbon steel. Also available in stainless steel.

FINISH:

None. (Zinc coatings available: consult factory.)

APPLICATIONS:

Stay-Form blind side wall ties

Adjustable length ties

One-sided forming

Applications

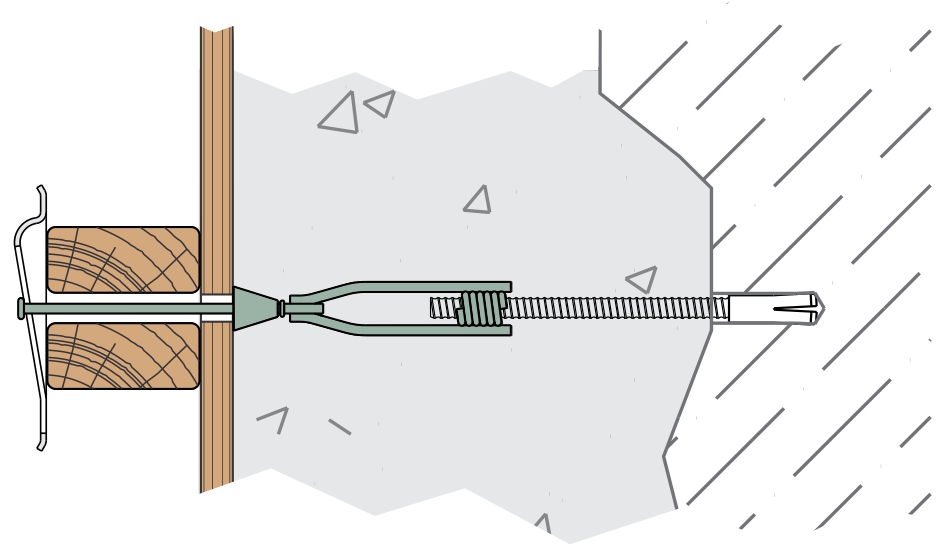

ONE-SIDED FORMING

EXISTING WALL

Snap-Coil™ Ties provide a simple and low-cost solution for securing formwork to existing structures for one-sided forming. They can eliminate additional hardware and labor over other methods.

Typical Existing Walls • Concrete • Wood Lagging • Brick •Sheet piling • Hollow concrete block • Rock

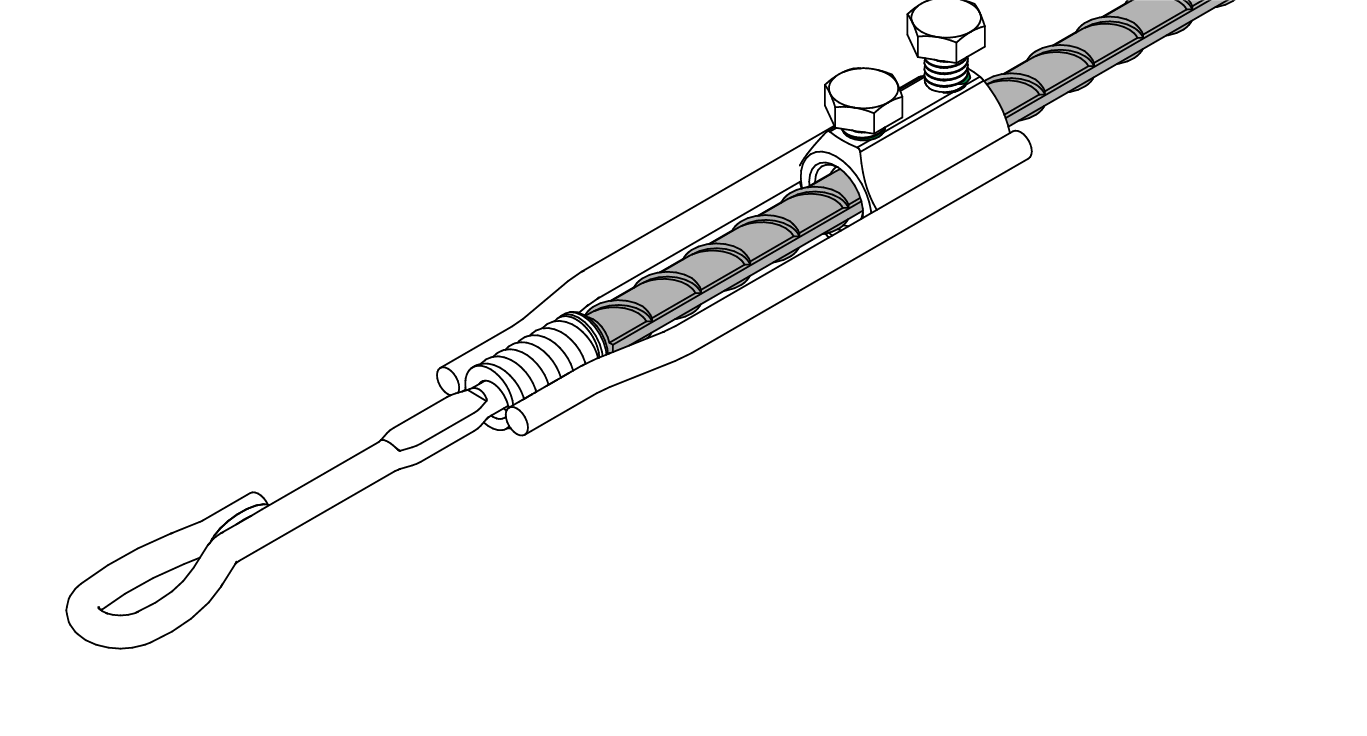

ADJUSTABLE LENGTH TIES

Snap-Coil™ Ties can be threaded back-to-back to create long- or unusual-length ties with different end configurations. For example, a 27½” tie with a long tail on one end and a short tail on the other can be easily assembled on-the-spot from standard components

Typical Applications • Battered walls • Mass pours • Pile caps • Pilasters

ANCHORING MEANS

Depending on the existing wall material and the design tie loads, the threaded rod may be secured with:

Drop-in anchors

Epoxy

Pivot brackets

Plate washers and nuts

Toggle ties

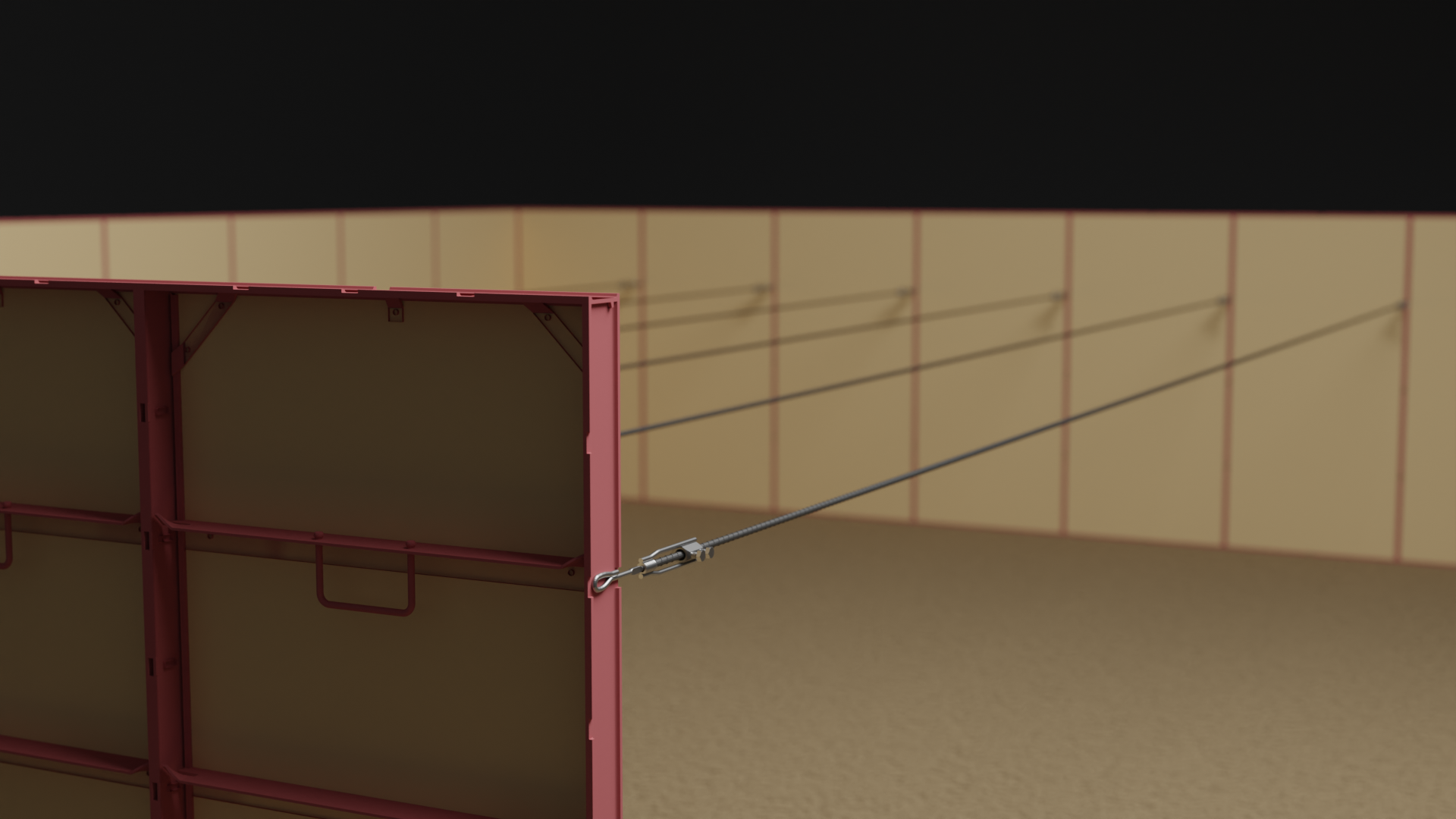

BLIND SIDE WALLS

Steel Dog® Snap-Coil™ Ties and Rebar Hooks provide a fast and low-cost way to use Stay-Form® stay-in-place expanded metal mesh to form blind side walls (where clearances on one side are too tight to allow for removal of reusable forms).

•Lower labor costs • Field adjustable length

•Standard components mean no need for custom parts