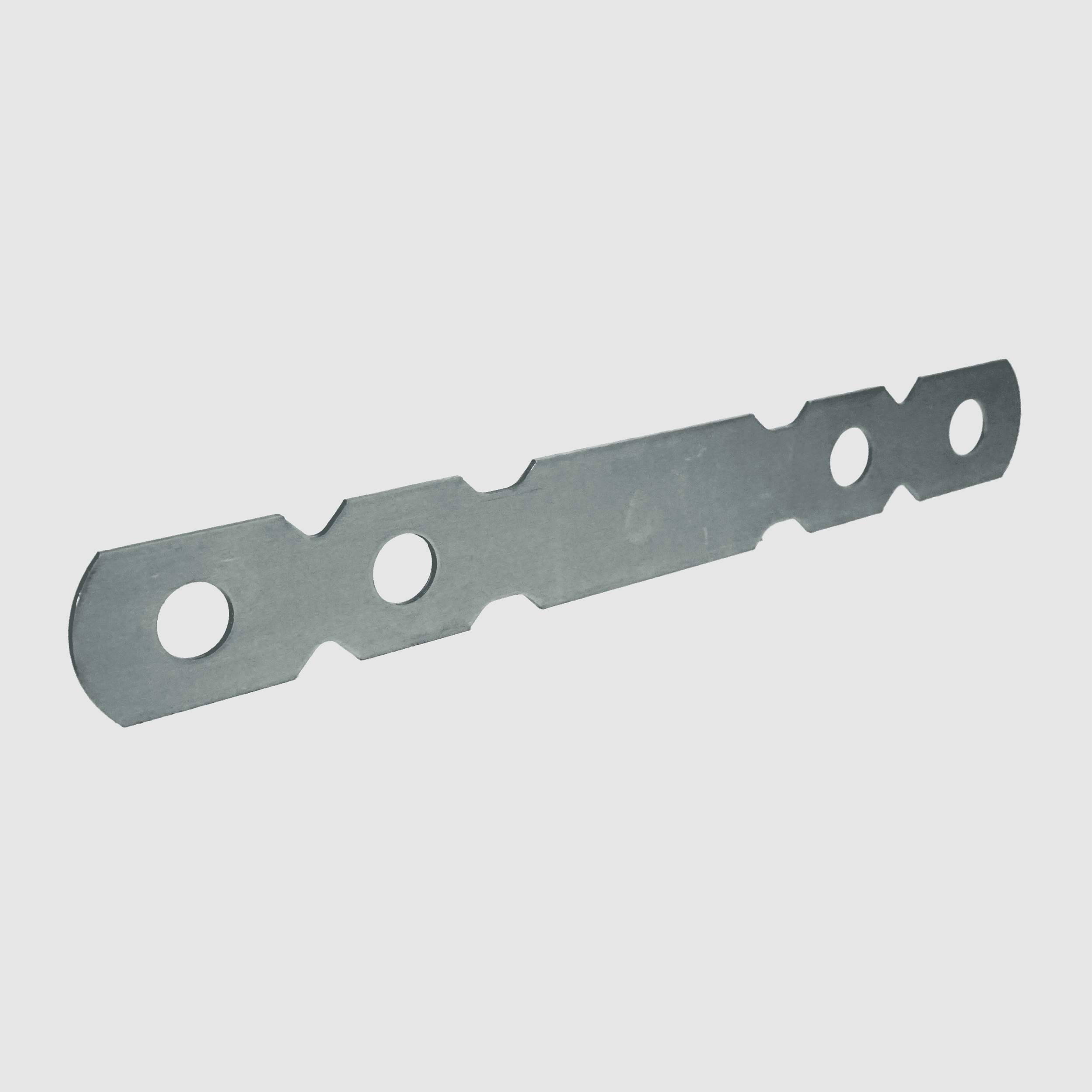

Fiberglass Loop Ties

Fiberglass Loop Ties

Fiberglass offers many advantages over steel—it never rusts, it resists water seepage, and it eliminates the need for breakback requirements and patching. However, until now it has been a difficult and expensive material to work with—requiring special hardware, and a tremendous amount of labor.

Available in wall sizes 4”-32” including fractional sizes.

(For sizes over 32” contact factory for options)

Click here for more detailed information about installation and and applications.

Patent# 10,907,365

Features:

•Eliminates need for cones

•Non-Magnetic

•Non-Corrosive

•Low thermal conductivity (for insulating applications)

Material:

Epoxy coated fiber thread, tinted grey to match concrete color for cosmetic applications

Maximum Safe Working Load:

2800 lbs (based on a 2:1 safe-working-load)

Applications:

•Architectural/exposed concrete walls

•Water treatment facilities

•Insulated concrete walls

•Applications where steel or rust is a concern

•The Fiberglass tie lends itself perfectly to any application where conventional steel loop ties are discouraged or prohibited, as well as places where stainless ties or deep breakbacks are required. They can also be used alongside conventional steel ties to address a critical section of a wall.

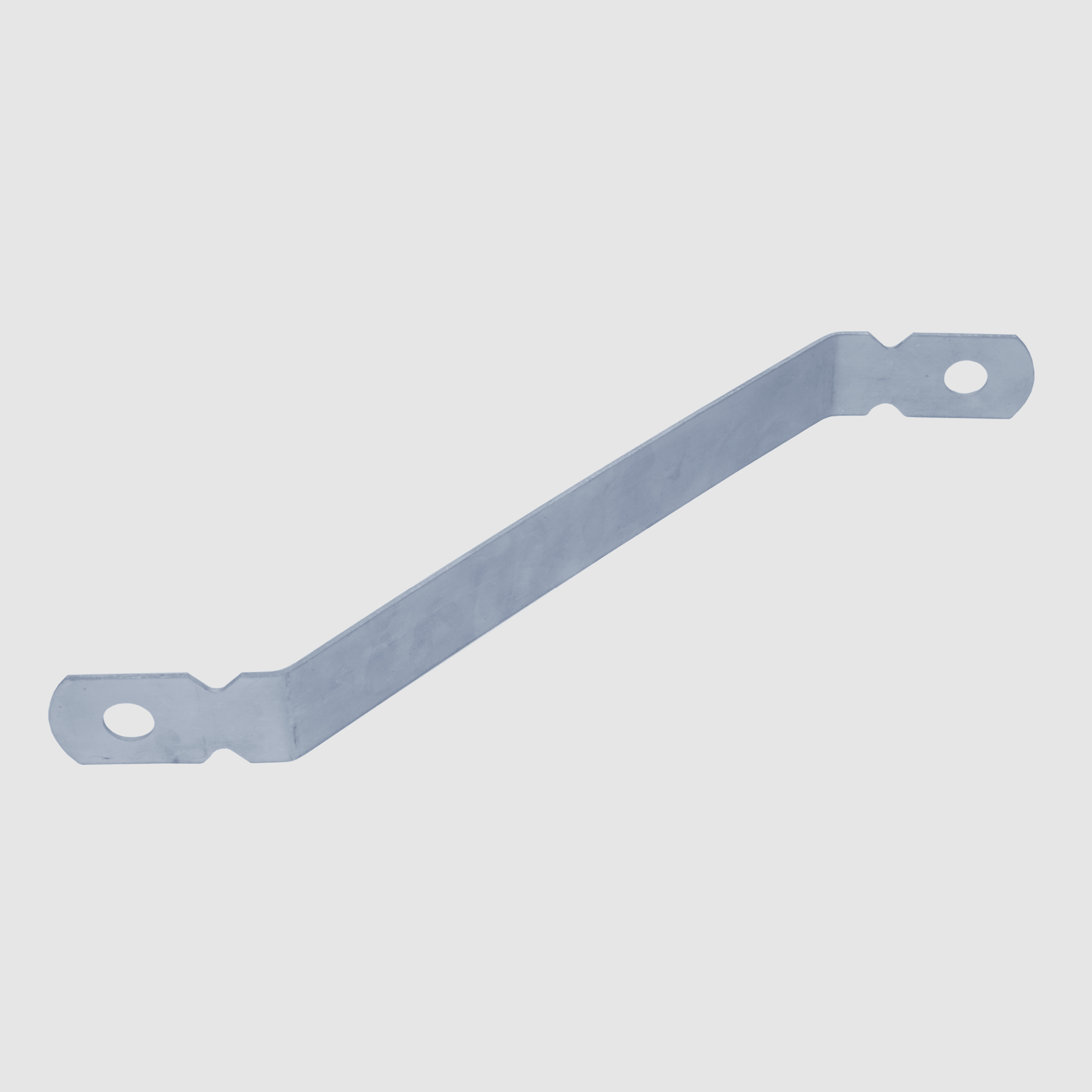

Installation:

Fiberglass Ties should be installed like their steel counterparts. Set up formwork and fasten ties in place with wedge bolts

Stripping

•After stripping panels break the thimbles off with a hammer or use an angle grinder or multi-tool. NO PATCHING REQUIRED

•For exposed walls where appearance is critical, use a shim stock backing around the tie to protect the finished wall from the grinder.